Project Description

With the advent of better plastics in the early 1980s, and the then-threat of the little understood HIV/AIDS virus, the market for disposable medical devices exploded. A culture in healthcare has since enshrined the belief that disposables are safer, less expensive, and more convenient (The Verge, March 2020).

Only in recent years have environmental Life Cycle Assessments (LCAs) demonstrated the impact of waste as a factor that calls the practice into question. LCAs look at a product’s impact on air, water, and land from its creation to end of life. These studies show that overall, it’s better for the environment to reuse or reprocess products than it is to create new ones each time. Now, calls are beginning to emerge from within the MedTech industry for a circular economy for healthcare (Medical Device & Diagnostic Industry, October 2020).

From a regulatory perspective, medical device requirements view devices as either reusable (multiple-use devices such as a hospital bed or linen) or disposable (“single-use” medical devices (SUDs) such as surgical blades, pulse oximeters cables, transfer mats or syringes). A reusable medical device can be repeatedly reused assuming the reprocessing technicians in hospitals adequately disinfect, clean, and sterilize the equipment in compliance with the reprocessing instructions provided by the original equipment manufacturer (OEM). Alternatively, a device marketed as disposable or for single-use can only be used on one patient.

An FDA-Regulated Solution

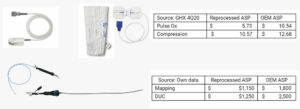

The FDA has found that many medical devices labelled by their OEM for single-use can be collected, shipped, traced, cleaned, tested, disinfected and/or sterilized, repackaged, and returned to hospitals for safe reuse – without disrupting current healthcare practices or forcing clinicians to change their treatment approach. Commercial reprocessing of SUDs has been a tried-and-true practice for reducing costs, waste, and emissions for U.S. hospitals for two decades. Germany, the United Kingdom, Canada, and Japan are among a dozen other countries with successful, regulated reprocessing solutions.

The FDA has found that many medical devices labelled by their OEM for single-use can be collected, shipped, traced, cleaned, tested, disinfected and/or sterilized, repackaged, and returned to hospitals for safe reuse – without disrupting current healthcare practices or forcing clinicians to change their treatment approach. Commercial reprocessing of SUDs has been a tried-and-true practice for reducing costs, waste, and emissions for U.S. hospitals for two decades. Germany, the United Kingdom, Canada, and Japan are among a dozen other countries with successful, regulated reprocessing solutions.

Manufacturers have enormous incentive to label devices for single-use. First, to market a device as reusable under FDA requirements, the manufacturer needs to submit validated cleaning and reprocessing instructions (FDA Final Guidance, 2015). Simply labeling a device for single-use is far less expensive and time consuming than labeling it as reusable. Second, by marking devices for single-use, manufacturers create an unending demand for their product. Medical device sales representatives and the companies that employ them make more money the more products they sell.

Hospital skepticism of the single-use label was noted in a 2000 U.S. Government Accountability Office (GAO) Report. According to the report, healthcare personnel “distrust the single-use label for some devices” because, among other things, the regulator “cannot require manufacturers to support the designation of a device as single-use,” and “they perceive that manufacturers have an economic incentive to market devices as single-use that could just as well be sold as reusable” (GAO, June 2000).

The environmental impact of decisions to encourage SUDs should not be minimized. In the U.S. and Canada, over twelve million pounds of medical waste comprised solely of SUDs were diverted from landfills and incinerators through regulated reprocessing programs in 2020 alone (AMDR member-supplied data).

With increasing awareness of the facts behind labelling and the knowledge that the FDA requires reprocessed devices to be substantially equivalent to the original device, including safety and in function, the SUD commercial reprocessing industry has blossomed, roughly doubling in size yearly, since 2000. For more information, visit www.AMDR.org.