Project Description

Create Your Reprocessing Policy

AMDR has created a template Reprocessing Policy for you to modify and use as your own to alert vendors that your health system purchases commercially reprocessed SUDs. You should not tolerate any vendor who interferes with this decision. Click here to download the Reprocessing Policy template.

More than 9,000 hospitals and surgical centers use regulated, commercially reprocessed “single-use” devices (SUDs), allowing them to save at least 30 to 50% on costs compared to new devices. When health systems use reprocessed SUDs, they also reduce waste, cut greenhouse gas emissions, and enhance supply chain resilience by keeping devices domestically sourced and using them more than once. Note: in the EU, SUD reprocessing is referred to as remanufacturing.

But many health systems are not fully capitalizing on the cost-saving and environmental benefits possible through reprocessing. AMDR has identified the most important steps you can take to create or expand a reprocessing program. One key issue: minimizing threats from some original equipment manufacturers who are financially incentivized to thwart reprocessing programs. For that, we’ve created a sample Reprocessing Policy (see box) to help inform your vendors that reprocessing is here to stay at your hospital or surgical center.

Whether you are looking to start a new reprocessing program or optimize your existing one, below are some recommended steps to help you make the most of it.

- Measure the Benefits of Your Reprocessing Program

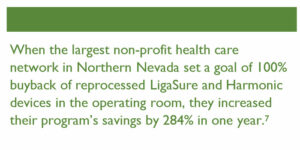

Quantifying the savings and environmental benefits of your reprocessing program is crucial. Cost savings can be quickly estimated by multiplying the number of reprocessed devices by at least 30 to 50% of their original cost, depending on negotiated prices. Larger devices, like transfer mats offer even waste reduction, which translates to additional savings. Use tools like our free CO2 emissions reduction calculator – as well as a large, growing body of research and advanced life cycle assessments – to ensure your program is supported by clear data and measurable benefits.

- Understand Your Reprocessing Partners

Engage with reprocessors who align with your hospital’s systems and schedules. A good reprocessor will seamlessly integrate with your existing inventory management, purchasing, and collection processes, ensuring that your program runs smoothly. Transparency in how devices are collected, cleaned, and tested is critical to maintaining high standards and trust in reprocessed devices. Consider arranging a tour of a reprocessing facility to see these practices firsthand. Show them your Reprocessing Policy (see box above) and make sure they agree to it.

- Commit to Sustainable Procurement

Sustainable procurement is key to reducing greenhouse gas emissions and waste. Use resources like Practice Greenhealth’s Sustainable Procurement Guide to assess the environmental impact of your supply chain and other Scope 3 emissions. Set ambitious collection goals: even if 100% collection is not feasible, research has shown that high rates of collection significantly increase the effectiveness of a reprocessing program. Continuous improvement and regular auditing of your program will help maintain its effectiveness and alignment with your sustainability goals.

- Simplify Collection Processes

Simplify the collection of used SUDs by having your reprocessing partner train staff on proper procedures and ensuring that collection containers are easily accessible. Collaborate with your reprocessing partner to identify the most effective collection strategies. Small changes, like reducing the size of red sharps bins in operating rooms, can significantly improve collection compliance and the overall efficiency of your program.

- Engage With Staff

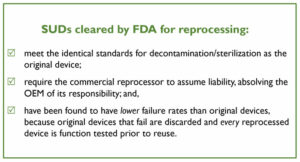

Secure buy-in from leadership and clinicians by emphasizing the financial and environmental benefits of reprocessing. Clear communication about the importance of reprocessing in reducing costs and emissions can drive compliance. Remind staff that exhaustive evidence shows no increased risks from reprocessed devices, and that in fact, reprocessed devices appear to fail less often than original ones. Regularly update staff on program successes and incorporate feedback to maintain engagement. As most healthcare workers want their workplaces to do something about climate change, underscore that through reprocessing, they are personally contributing to the solution.

- Advocate for Continuous Improvement

Regularly audit your sustainability program and advocate for new science and technology that can further reduce emissions and costs. If your organization lacks a sustainability officer, consider creating this role to drive green decision-making. Use visual data to communicate the impact of your reprocessing program, both internally and externally, to build broader support.

Additional Considerations and Resources

Beware of Anti-Reprocessing, Anti-Competitive Behaviors

Be aware of anti-competitive tactics that some original equipment manufacturers (OEMs) use to hinder your reprocessing efforts. Research has shown that these behaviors are a major barrier to the success of reprocessing programs. AMDR has chronicled these problems for years. Common anti-reprocessing business tactics include:

- OEM “chipping,” or use of ePROMs, specifically to render reprocessed devices inoperable.

- Similarly, OEM “updating” software that disables the use of reprocessed devices on hospital generators and consoles without hospital permission or notification, or, by misleading hospital personnel as to true nature or the anti-reprocessing impacts of such “upgrades.”

- OEM threats to void warranties or case support when reprocessed SUDs are used in a procedure.

- Unfair contracting such as restricting hospitals’ ability to reprocess in exchange for discounts, or “free” equipment in exchange for minimum purchasing requirements which undermine reprocessing programs.

- Price gouging: for example, in the EP space, a several fold price increase for the reprocessable version of a device intended to push hospital towards the nonreprocessable version of a similar device.

- Interference with hospital assets such as replacing cables without hospital permission to make reprocessed SUDs inoperable; moving or rearranging hospital stock of reprocessed SUDs to push hospital use of only new SUDs; moving/hiding SUD reprocessing collection containers and/or disposing of the contents of the bins; finally, instruction to surgical or EP physicians to destroy hospital medical devices assets to prevent reprocessing. Treat such actions as asset tampering and revoke vendor access privileges immediately.

- “Recycling programs” that seem to target only the devices that FDA regulates for reprocessing. AMDR is aware of competing vendors who appear to be sabotaging reprocessing programs by collecting devices for “recycling” when in fact these devices end in incineration or the trash.

- Publication of misleading medical studies that purport to show “dirty” reprocessed devices. However, the chain of custody seems to always point back to the OEM, as opposed to a hospital customer, resulting in retractions or information warnings from editors.

The U.S. government takes this very seriously, and a consortium of federal agencies including the Federal Trade Commission, the Department of Health and Human Services, and the Department of Justice’s Antitrust Division have created an online portal accepting anonymous reports of such behaviors. If you know of or have ever witnessed these anti-competitive tactics, please consider submitting a complaint to the government.

Additional External Resources

Reprocessing “Best Practices”

- Maximize your reprocessing program

- Transparency in reprocessing: A healthcare provider’s checklist

- Profitable, sustainable reprocessing programs: A healthcare provider’s checklist

- Patient safety in reprocessing: A healthcare provider’s checklist

Anti-Reprocessing, Anti-Competitive Tactics